Nitrile Gloves: Choosing the Right Thickness for Food Processing

When it comes to choosing a disposable glove, nitrile gloves are a leading choice due to their affordability, dexterity, durability and of course sensitivi

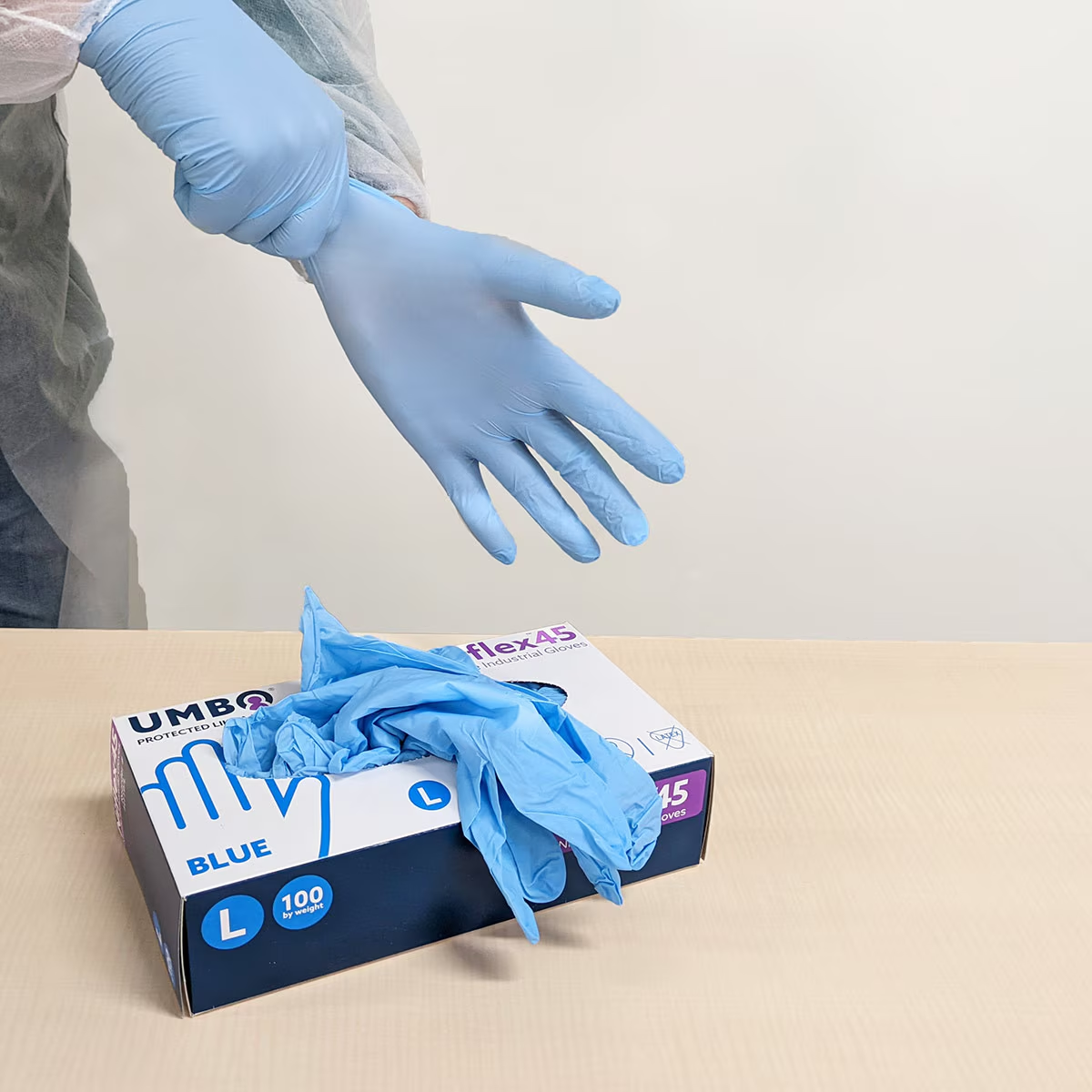

When it comes to choosing a disposable glove, nitrile gloves are a leading choice due to their affordability, dexterity, durability and of course sensitivity. They offer superior protection against chemicals, acids, oils, cuts, and abrasions, making them ideal for protecting hands from common hazards encountered in food handling.

But did you know that nitrile gloves come in various thicknesses, each offering a different level of protection and dexterity? Choosing the right thickness for your application is vital for ensuring both safety and performance. Here at Amerisan, we understand the importance of proper glove selection, and we're here to guide you through the levels (mils) of nitrile glove thickness.

![]()

![]()

Why They're Top Choice for Food Processors

Nitrile gloves stand out for several reasons, making them the preferred option for food safety:

- Latex-Free: For those with latex allergies, nitrile gloves provide a safe and comfortable alternative.

- Chemical Resistance: They offer excellent protection against a wide range of chemicals commonly found in food processing environments, such as oils, greases, and cleaning solutions.

- Puncture Resistance: Nitrile gloves are known for their superior puncture resistance, safeguarding hands from cuts and scrapes caused by sharp utensils or bones.

- Dexterity and Tactile Sensitivity: Compared to other materials like vinyl, nitrile gloves provide better dexterity and tactile sensitivity, allowing for a higher degree of precision when handling food.

- Versatility: Nitrile gloves come in a variety of colors, which can be valuable in implementing HACCP programs. Color-coding gloves can help prevent cross-contamination and accidental foreign material contamination.

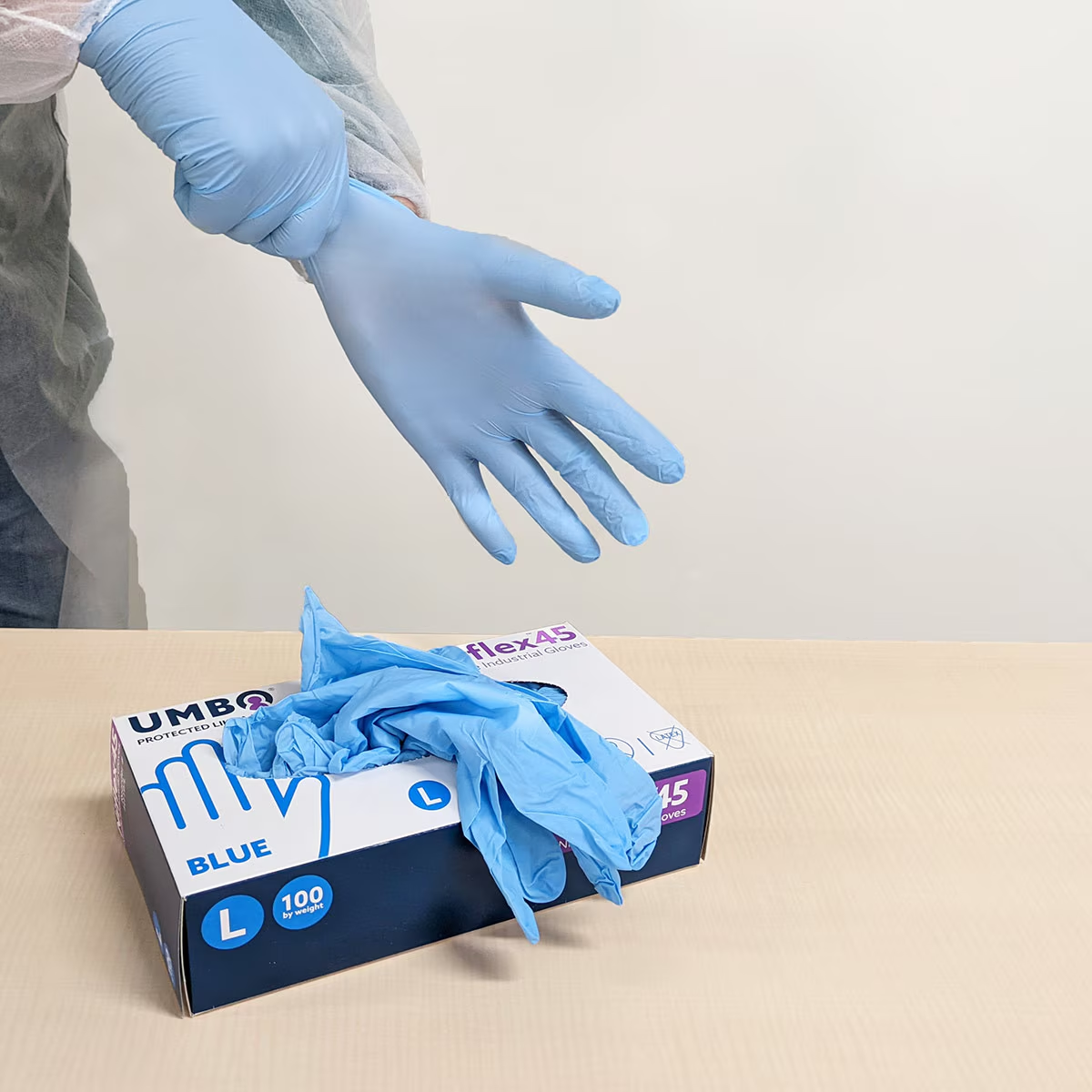

Understanding Nitrile Glove Thickness Levels

Nitrile gloves come in various thicknesses measured in mils, with one mil being one-thousandth of an inch. Thicker gloves provide greater protection but less dexterity. Amerisan is here to help you choose the best thickness level to help with job performance.

Here's a general breakdown of nitrile glove thickness levels:

- Thin (2-3 mils): These lightweight gloves are perfect for tasks requiring maximum dexterity and minimal protection. Examples include handling pre-washed and prepped fruits and vegetables, bakery applications like garnishing pastries, or arranging food on platters.

- Medium (4-5 mils): This versatile thickness offers a well-balanced combination of dexterity and protection. They are ideal for most general food processing tasks, such as meat processing, packaging finished products, or handling dry ingredients. The increased thickness compared to thin gloves provides better puncture resistance, making them suitable for handling some sharp objects like knives or box cutters.

- Thick (6-8 mils): When dealing with jobs requiring enhanced puncture resistance and protection from chemicals or oils, opt for thicker nitrile gloves. These gloves are ideal for heavy-duty food processing applications like butchering meat, handling poultry, or processing raw fish. The added thickness provides a significant barrier against cuts, punctures, and exposure to oils and greases.

Important considerations when choosing your thickness

Important considerations when choosing your thickness

Dexterity vs. Protection: Always prioritize the task at hand. If the job requires maximum dexterity, prioritize a thinner glove. However, if the focus is on protection from cuts, chemicals, or oils, opt for a thicker glove.

Frequency of Glove Changes: Thinner gloves may tear or puncture more easily, requiring more frequent changes. This can add to overall costs. Consider the cost-effectiveness of using a slightly thicker glove that offers extended wear.

Comfort: Wearing gloves for extended periods can lead to hand fatigue. Choose a thickness that provides adequate protection while maintaining comfort throughout your workday.

The Amerisan Difference

At Amerisan, we offer a wide range of high-quality nitrile gloves in various thicknesses and colors to meet the specific needs of your food processing operation. We understand that choosing the right glove is critical for maintaining a safe and efficient work environment.

Our knowledgeable team is always happy to assist you in selecting the perfect nitrile glove thickness for your specific applications. Contact us today to discuss your food processing needs and find the ideal glove solution for your team.

Remember, the right glove thickness ensures optimal protection for your employees while maintaining the dexterity they need to perform their jobs efficiently. Let Amerisan be your partner in achieving the highest standards of food safety and employee well-being.